The Maxim Integrated MAX14919 industrial-protected quad-channel lowside switch features 140mΩ...

Read MoreFTM / Intelligent Sensing / Future Electronics — How Thermal Pixel Array Sensors Support New Building Automation

By Davide Osto

EMEA Business Development Manager for Sensors, Future Electronics

Loft and wall insulation, double glazing, and LED lighting have together greatly reduced the thermal and electrical energy consumption of residential and commercial buildings in the past 50 years. But despite these advances, building operations still suffer from various inefficiencies.

For instance, under-utilized space means that many buildings are larger than they need to be for the number of people occupying them, especially since the Covid-19 pandemic has extended the practise of working from home. Energy continues to be wasted because spaces are lit and heated even when unoccupied. And conventional technologies for heating indoor space ineffectively deliver warmth and comfort to the users of the space.

The root cause of this inefficiency has until now been the weak link in all building control systems: people. It is unfortunately true that human beings routinely leave lights on when they leave a room, book meeting rooms and then fail to show up for the meeting, and set the target temperature too high on entering a cold room.

This implies that, if buildings could be made more self-regulating, both the planet and building operators would benefit: enhanced building automation would cut the greenhouse gas emissions produced by buildings’ heating, ventilation and lighting systems, while also cutting running costs.

Progress towards this desirable outcome is now being accelerated by three concurrent trends. First, regulations applied worldwide to commercial and domestic buildings are tightening requirements to meet minimum standards for parameters such as energy efficiency and indoor air quality.

Second, organizations worldwide which own or operate office buildings are planning for a post-pandemic world in which fewer workers occupy offices and more work from home.

Third, the commercialization of mainstream, affordable semiconductor technology supporting rich data-driven Artificial Intelligence (AI) is enabling machines to perform decision-making operations that call for human-like interpretation of complex and ambiguous data sets such as image files.

As a result, OEMs which make products such as Heating, Ventilation and Air-Conditioning (HVAC) equipment, security and access control devices, lighting controls, and building automation systems are eagerly eyeing the opportunity to take a share of a market which was worth an estimated $75bn in 2020.

Some of the value of next-generation building automation systems will be in the technology for detecting occupancy, for counting people, and for measuring the temperature of indoor spaces. All of these functions can be performed through thermal sensing of infrared radiation.

Here too, advances in technology are enabling new functionality and the more sophisticated operation of systems such as lighting controls, heating controls, and ventilation.

Remote far-infrared thermal sensing provides an ideal means for detecting objects which emit infrared radiation, across a broad spectrum of wavelengths. Thermal imagers detect part of the heat radiation spectrum, for example between wavelengths of 700nm and 1,300nm. Thermal sensors do not operate in the visible light spectrum, so require no means of illumination and work as effectively in daylight as at night. Since an infrared thermal sensor can measure temperature remotely and accurately, the same device may potentially be used to detect thermally transmissive objects such as human bodies and also to measure surface temperatures.

These functions are of high value in intelligent building automation systems, where they may be used to:

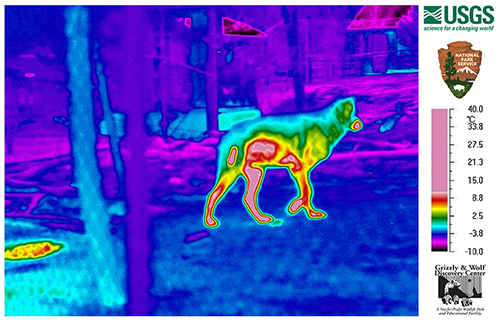

Fig. 1: A thermal camera’s detailed image of a wolf in Yellowstone National Park, pictured by the US Geological Survey. (Image in the public domain)

Until recently, these applications for thermal occupancy detection in building automation could only viably draw on two types of thermal sensing device, both of which have serious drawbacks. On the one hand, a full-blown infrared camera or thermal imager provides a very detailed video picture of the heat profile of a scene, even to the extent of allowing the viewer to watch what the occupants of a room are doing (see Figure 1). This is valuable in security and surveillance equipment, for instance. But in building automation systems, the privacy of occupants is subject to strong legal protection, which means that the use of an infrared camera would call for the strict implementation of onerous data protection and safeguarding protocols.

Since building automation systems do not need to identify individuals or support monitoring of their activity, and since infrared image sensors are expensive, this technology is fundamentally unsuitable.

At the other end of the market are simple Pyroelectric Infrared (PIR) sensors, familiar to most people as the motion-detection device which triggers security lights and intruder alarms. These devices are cheap, but are unable to detect static occupants. In addition, they simply detect the motion of IR-emitting objects around the 10µm wavelength and do not measure temperature.

These two sensor types leave a gap in the middle for a sensor that can produce a heat map with sufficiently detailed temperature data to be useful, without compromising the user’s privacy.

This is the gap that Melexis has sought to fill with the MLX9064x series of thermal pixel array sensors. The first product in the series, the MLX90640, produces a 764-pixel (32px x 24px) thermal picture (see Figure 2). It is supplied in two versions, one with a field of view of 55° x 35° and the other, 110° x 75°.

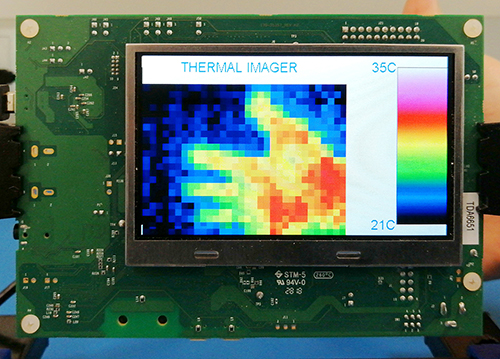

Fig. 2: Thermal image of a hand produced by an MLX90640, and displayed on a Tianma color LCD mounted on the back of Future Electronics’ Sequana reference design board. (Image credit: Future Electronics)

When used in a large indoor space such as an office meeting or conference room, the 32px x 24px resolution of the MLX90640 is low enough to prevent identification of occupants or personal details, but high enough to enable a system to count the number of occupants. By dividing the sensor field of view into pixels, the sensor also enables relatively detailed mapping of the temperature profile relative to occupancy. This allows temperature settings to be aligned with the actual experience of the user in the room, rather than to meet a global temperature target set and measured at a wall-mounted thermostat which is some distance from the occupants.

Supplied in a standard 4-pin through-hole mount TO39 package with integrated optics, the MLX90640 is small enough to be accommodated in many types of host devices, including ceiling-mounted luminaires, wall- or ceiling-mounted ventilation units, table-top air purifiers, or even smart speakers.

Crucially, design engineers can use the data provided by the MLX90640 with a high degree of confidence: high typical accuracy of ±1°C is offered across the full measurement range of -40°C to 300°C. This high accuracy is due to the unique Melexis pixel design which features very low noise impairment of the infrared signal: the Noise Equivalent Temperature Difference (NETD) rating is 0.1Krms at a sampling frequency of 1Hz.

A thermal pixel array such as the Melexis MLX90640 presents no difficulties to the design engineer implementing the hardware design. There are only four pins: two for the power supply, one for an I2C interface’s clock input, and one I2C serial data input/output.

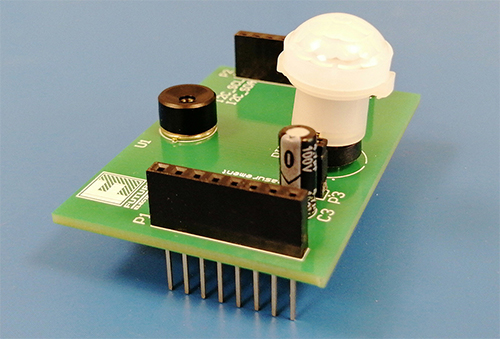

Fig. 3: The Future Electronics Sequana Thermal reference design board, showing the MLX90640 (left centre) and a Panasonic EKMB1393111K presence detector (right centre). (Image credit: Future Electronics)

The potential for difficulty arises in implementing firmware and software appropriate to the application. Over the I2C interface, the MLX90640 can provide temperature data on each of 764 pixels. Detailed register settings allow for adjustment of parameters such as gain, sensitivity, offset, and resolution. This firmware is external to the sensor as it is hosted in a microcontroller or applications processor.

Development of this firmware from scratch would be a substantial engineering task. Fortunately, OEMs can accelerate evaluation timescales. That is because Melexis supplies microcontroller driver software, which is freely available online[1]. The driver is written for the Arm® Mbed™ platform, which is today in widespread use and is familiar to many embedded development engineers.

Development of proofs-of-concept for new building automation equipment designs may be accelerated even more through the use of a new reference design board produced by the Future Electronics Centre of Excellence development laboratories. The new Sequana Thermal system consists of a thermal sensing daughterboard (see Figure 3) connected to either of two controller boards which drive a 4.3” color LCD monitor.

The sensor daughterboard features an MLX90640 together with an EKMB1393111K Panasonic PIR motion sensor. In a ‘real world’ use case, the very low-power PIR sensor may be used to wake up the MLX90640 from sleep mode to keep the power usage of the sensing system to a minimum. Devices in the Panasonic EKMB family feature a choice of lenses, and operate from a stand-by current of 1µA, 2µA, or 6μA, to serve different applications.

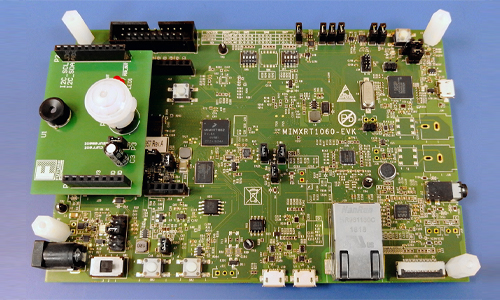

The developer has a choice of two controller boards, based on either the STMicroelectronics STM32F746G 32-bit microcontroller, or NXP Semiconductors’ i.MX RT1050 applications processor/microcontroller crossover device (see Figure 4). The Sequana Thermal system is supplied with the Melexis firmware running on the Mbed platform, enabling the developer to start evaluating out of the box the thermal sensor’s performance in their application. This evaluation is made easier because the thermal data produced by the sensor may be visualised on the color monitor, as well as exported to a host PC via the board’s USB interface.

Fig. 4: The Sequana Thermal board (left) mounted on the Sequana embedded computing main board. (Image credit: Future Electronics)

By integrating the MLX90640 into end products such as luminaires, lighting controls or thermostats, OEMs can enable sophisticated new people-counting and heat-mapping functions. The output from the device can drive sophisticated building management systems which can improve user comfort and reduce energy wastage, while keeping the operator immune from concerns about privacy violations.

By beginning development of an MLX90640-based design with the Sequana Thermal board as a proof-of-concept, the designer can rapidly see how the sensor performs in the intended application.

Board part number: Sequana Thermal

Reference

[1] Melexis driver software available at https://github.com/melexis/mlx90640-library.git

Share This

Get access to the latest product information, technical analysis, design notes and more

Sign up for access to exclusive development boards, an essential tool for many innovative design projects.

*Available to pre-qualified EMEA customers only.

The Maxim Integrated MAX14919 industrial-protected quad-channel lowside switch features 140mΩ...

Read MoreInfineon's TLI4971 Series comprises of precise and stable coreless magnetic...

Read MoreThe ZMOD4510 from Renesas is the first software-upgradeable, digital outdoor...

Read More