FTM / Motion/Motor Control / onsemi — Motor Control Design Guide

Today, most battery-powered devices use three-phase brushless dc (BLDC) motors because of the high efficiency and smooth power delivery, which make them ideal for high-power and industrial applications. For designers of a BLDC motor system, some important factors affecting component selection apply particularly strongly to battery-powered applications.

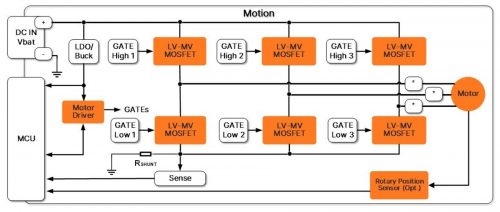

Every motor needs a motor controller to precisely control speed and torque. The motor control system is comprised of three major subsystems, shown in Figure 1. First is the controller, which can be a microcontroller. The controller output is a low-voltage PWM signal which sets the speed of the motor.

Next is the gate driver, which takes the low-voltage output from the controller and amplifies the voltage and current to drive a switch.

Finally, the switches supply voltage/current in turn to the three windings in the motor to generate torque.

Fig. 1: The three subsystems of a motor controller

Applications that use battery-powered motors

Battery-powered applications can be divided into two main categories, shown in Figure 2: low-voltage/low-torque, and high-voltage/high-torque. Each requires different components and solutions.

Low-voltage applications consuming up to about 3 kW include power tools such as drills or sanding machines, garden tools such as lawn mowers and leaf blowers, and drones. This category can also include more expensive products such as electric bikes, automation robots, and mobility scooters.

High-voltage applications, which consume from 3 kW up to 40 kW, range from electric scooters, automated guided vehicles (AGVs) and golf carts at the low end, to autonomous mobile robots (AMRs), electric tractors and electric/autonomous forklifts at the high end.

Fig. 2: Battery-powered end products

In motor control designs, the type of power switch is a crucial decision. For low-voltage applications, power switches with a low breakdown voltage are preferred because of the smaller footprint and lower cost. On the other hand, transistors with a higher breakdown voltage are required to handle the increased power demands and to ensure reliable operation in higher-voltage applications.

High-level system block diagram

A typical system block diagram for a three-phase BLDC motor is shown in Figure 3.

Fig. 3. Typical system block diagram of a three-phase BLDC motor

A three-phase BLDC motor requires a three-phase inverter consisting of three half-bridges, a total of six MOSFETs. The three-phase full-bridge topology with proper control algorithms enables precise control over motor speed and direction, resulting in the efficient and reliable operation of battery-powered tools. The motor-control function uses a PWM signal to set the commutation status to either the On or Off state.

Gate drivers serve a critical role in controlling MOSFETs. They translate low-power control signals from the motor controller or microcontroller into high-power signals capable of driving the MOSFETs effectively. A gate driver ensures that the MOSFETs switch on and off rapidly and efficiently, enabling precise control over the motor speed and direction. They also provide protection features such as over-current and over-voltage protection to safeguard the motor and the drive circuitry.

Position sensors measure the rotation of wheels or other moving parts to accurately track the position and orientation. The sensors can be employed as part of the electronic commutation of the BLDC control system. Inductive encoders offer many advantages over traditional optical or magnetic sensors. They are robust and lightweight, simplifying the overall design of the system, and are not sensitive to vibration or contamination.

Characteristics of motor controllers

The industry continues to focus on improving motor controllers. The desire is to make them smaller, more efficient, more reliable, and capable of driving more powerful motors. This requires enhanced performance in the components and subsystems that make up the motor controller.

The starting point for any motor controller design is the voltage rating of the switching transistor. The dc motor sets the required dc voltage: this determines the voltage rating of the switching transistors. These transistors need a safety margin above the required voltage. For field-effect transistors (FETs), the most important rating is the maximum drain-source voltage. For example, a dc motor operating at 100 V dc would use a FET with at least a 150 V drain-source voltage rating to ensure a 50% safety margin, which is essential for high reliability.

The next consideration is efficiency. Switching transistors consume power in two ways: through switching losses and conduction losses. Choosing the optimal combination of dV/dt capability, determining the switching speed, and on-resistance, determining conduction losses, will generally result in the highest power density and efficiency in any given application. The benefits are smaller size and longer battery run-time.

The next choice is the gate driver. The required input voltage and current of the chosen transistor will determine which driver is required to turn it on and off. Once the combination of transistor and driver is chosen, designers can select additional components including the controller, LDOs, buck regulators, operational amplifiers and so on.

onsemi products and solutions for BLDC motors

onsemi offers a variety of power semiconductor technologies for transistors with different power and speed ratings, as shown in Figure 4.

Fig. 4: Power semiconductor technologies for transistors

Silicon MOSFETs strike a balance between performance, cost, and thermal management, making them a practical choice for battery-powered applications. The latest PowerTrench® technology from onsemi, a shield gate trench topology, offers ultra-low gate charge and on-resistance, which produce lower switching and conduction losses. Consequently, the PowerTrench T10 MOSFET family achieves both higher power density and reliability than previous technologies. This family is available with 40 V and 80 V ratings in multiple package options.

The choice of transistor will dictate the specification of the driver. One option is an isolated gate driver, which isolates the input and output of the driver. A rule of thumb is that if the motor’s power rating is less than 2.5 kW, then isolation is not needed. Otherwise, it is best to choose an isolated driver, as it avoids ground loops and protects users.

Other driver considerations include the amount of sink/source current required, the supply voltage, and whether an internal current-sense amplifier is required.

Finally, there are two different design approaches when selecting a driver. There are single-phase drivers, called high/low drivers, which drive both the transistors in a single phase. A three-phase motor requires three of these.

Three-phase drivers are also available, which contain six drivers. These single drivers, such as the onsemi FAN7888, drive the high and low side of all three phases of a motor.

Design support from the experts

As this guide shows, there are many considerations to take into account when choosing components for a battery-powered motor design. Partners such as Future Electronics and onsemi can provide expertise and advice to help to navigate designers through this process.

onsemi provides detailed information to help designers select the right motor-control components for battery-powered applications, including low- and mid-voltage MOSFETs, gate drivers, motor drivers and rotary position sensors.