When MOSFETs are being evaluated for a high-power design, engineers often make their choice based on the parameter of on-resistance.

Lower on-resistance means that the MOSFET will have a lower power loss, which in turn means it will generate less heat and provide for safer operation.

However, a MOSFET’s ability to handle a large current is not determined by its on-resistance alone, but also by its Safe Operating Area (SOA) rating. SOA, a characteristic specified in most MOSFET datasheets, is the amount of power which the device can handle for a period of time before failing. A strong SOA capability can make a power design more robust and reliable; conversely, a weak SOA rating indicates that a MOSFET is prone to failure under some expected fault conditions.

Fig. 1: Trench structure of a superjunction MOSFET

Some applications rely on a good SOA rating. For example, hot-swap power supplies will hold the MOSFET in linear mode at start-up to limit the in-rush current. Here, the MOSFET must handle a large amount of power for a short period of time to protect the load circuit: this calls for strong SOA performance.

Circuits which can encounter faults, such as power ORing or e-fuses, might be exposed to large fault currents for short periods of time: here too, the SOA rating is important. A MOSFET might fail if it cannot handle the power in the time needed to switch it off. In other words, during the fault and switch-off time, a MOSFET with a smaller SOA can fail, as it is incapable of handling the energy driven through it.

What Determines a MOSFET’s On-Resistance and SOA?

Most modern power MOSFET manufacturers use a variant of the trench design shown in Figure 1. To turn the device on, the gate has a voltage applied to it: this creates current carriers in the channel which connects the Drain and Source of the device. Each gate trench has two channels carrying current, one on each side of the trench. Applying a larger gate voltage creates more charge carriers in the channels, which in turn reduces on-resistance.

Another way to reduce on-resistance is to put more trenches in parallel. The effect is the same as when resistors are inserted in parallel in a circuit: adding trenches in parallel decreases on-resistance. To reduce on-resistance even more, trenches can be placed closer together to allow for more paralleling.

The trench itself acts as a heat-sink, allowing heat to pass through to the device’s package. Narrowing the trenches impairs thermal performance, and this reduces the SOA. This creates an inverse correlation between these two aspects of MOSFET performance: improving on-resistance tends to impair SOA.

What Happens if SOA Capability is Exceeded?

A MOSFET’s SOA dictates the amount of power the device can tolerate over a period of time before failure. There are two failure modes: it can fail either because the entire MOSFET overheats, or because a part, or so-called ‘hot spot’, overheats.

As the temperature of the device rises, the value of its threshold voltage falls, which dictates when the device turns on and off. This has the effect of lowering the device’s on-resistance. This effect is usually negated by a general increase in the MOSFET’s on-resistance as temperature increases.

When a hot spot is created, however, the device turns on more in that region, allowing for more current to flow through it. This in turn heats the area up further, reducing the threshold voltage and increasing current until the device fails. This effect is called thermal run-away: the device will fail under this condition.

When the MOSFET manufacturer puts channels closer together to reduce on-resistance, it increases the risk of hot spots, since the narrower structure reduces the current-carrying capability and thermal performance of each trench. Overheating and thermal run-away are the signs of failure caused when a MOSFET operates outside its SOA.

During excessive heating or thermal run-away, the device may also suffer from a short-circuit failure. The device will then act as a three-terminal short-circuit, with the Gate, Source and Drain pins shorted together, until the large current causes it to burn.

Avoiding the SOA/On-Resistance Trade-Off

Nexperia has created superjunction MOSFET technology which avoids the trade-off between on-resistance and SOA to which competing MOSFETs are susceptible. The Nexperia superjunction structure extends SOA performance by adding extra p-doped trenches between the gate trenches, to provide more charge carriers in the channel. This reduces on-resistance without affecting the SOA.

Another method used is ‘Super SOA’, which extends SOA performance. This allows Nexperia MOSFETs to offer competitive on-resistance while providing up to ten times higher SOA performance than competitors’ parts.

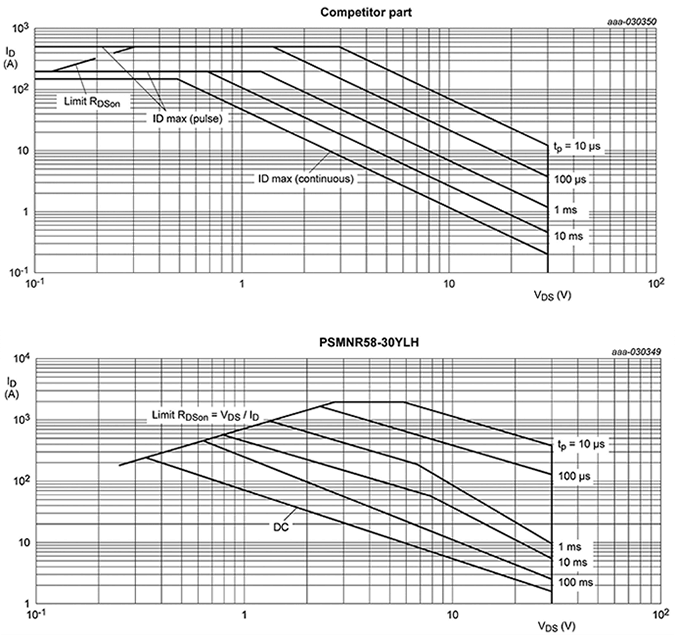

Fig. 2: SOA comparison of similar RDS(ON) devices

Understanding SOA Graphs

Figure 2 shows a comparison between a 0.67mΩ Nexperia MOSFET and a competing device with slightly lower on-resistance of 0.60mΩ. On the drain current, ID, axis, the difference between the two devices is of an order of magnitude. Each curve on the graph shows the time for which the device can safely handle a specific voltage at a specific current before failing.

For example, for a duration of 10ms when the voltage over the device is limited to 12V, the Nexperia device can handle a current of 30A; the competing device can only handle 2A.

This indicates the strength of Nexperia’s SOA performance. A wide range of applications might benefit from this characteristic. A good SOA capability gives the MOSFET a greater chance of surviving faults and unexpected transients which might damage or break another device.

Nexperia’s range of NextPower Live MOSFETs, which have superior SOA capability, are listed in the table to the left.