By Dr-Ing. Jan Preibisch, Application Marketing Manager, Nexperia

The drive circuits for high-performance, high-power LEDs tend to use boost-buck converters with complex controllers that require a deep understanding of the topology to create reliable designs which comply with EMC regulations.

For low- and mid-power LEDs, however, the driver circuit can be very simple and robust: the solution is to use a constant-current LED driver which operates as a simple linear regulator. It is true that constant-current LED drivers are less efficient and lose more power than switching power converters. But their excellent EMC performance, reliability and simplicity, as well as the markedly lower cost at the system level, make them the preferred option for driving LEDs at currents of up to 500mA.

Drivers referred to in this article with the prefix NCR are available from Nexperia. They are used in constant-current source and automotive applications such as interior and exterior lighting, including lights for door handles, dashboards, number plates, indicators and rear clusters.

Fig. 1: Low- and high-side constant-current LED driver topologies

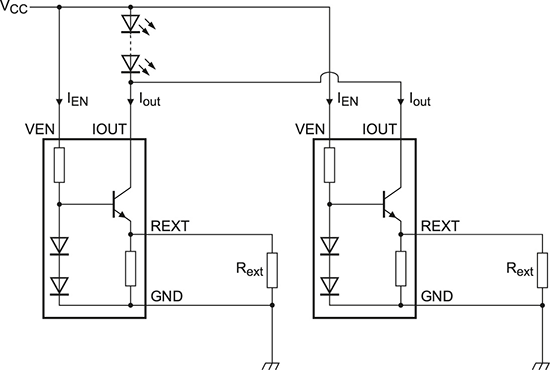

Figure 1 shows the basic circuits for driving LEDs with a single constant-current driver. Internally, such a driver consists of a Bipolar Junction Transistor (BJT), two diodes and two resistors. Constant-current drivers with a PNP BJT operate as high-side drivers, while those with an NPN BJT are low-side parts. One resistor defines the minimum output current; the other tunes the bias voltage and plays an important role in the Enable function.

The high-side constant-current driver has an Enable pin which is connected to ground; both the driver and thus the LED can be turned off by disconnecting this pin. In practice, this is performed by a Resistor-Equipped Transistor (RET), as illustrated in Figure 1, or by a MOSFET.

Low-side drivers, on the other hand, need a certain potential to be enabled. NCRx20x series drivers require a voltage in the range of the supply voltage to enable them. The NCRx21x driver can be enabled at a much lower voltage of 3.3V. This part draws a current of around 1 to 2mA at the Enable pin so it can easily be driven by the output pin of a microcontroller or a logic device. This is convenient for turning the LED on and off, and also for dimming with a PWM controller.

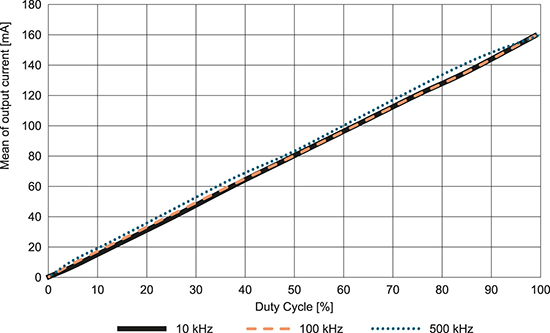

The dimming function is illustrated in Figure 2, which shows the mean of the output current as a function of the duty cycle for a NCR321Z driver for various switching frequencies with an external resistor of 6Ω. The graph displays a linear relationship between the duty cycle and the measured average output current. Even for frequencies above the recommended 10kHz, this linear relationship is maintained. The frequency should not exceed 10kHz however in the interest of compliance with EMC specifications.

Fig. 2: Mean of the output current as a function of the duty cycle of a NCR321Z constant-current driver with an external resistor of 6Ω

The output current of most constant-current LED drivers is adjustable by an external resistor. Some types are tuned to commonly used currents. As they do not feature an external resistor, they are available in three-pin packages. In circuits which include an external resistor, it will be in parallel to the internal resistor, thereby lowering the effective resistance.

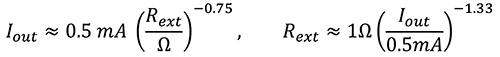

Low-side constant-current drivers with an NPN transistor – the NCRx2xx devices from Nexperia – have an internal resistor of 95Ω. An analysis of the measurement curves produces the following formula which enables the relationship between external resistor and output current to be estimated:

The value of the external resistor must not be so low that the maximum output current is exceeded. The majority of the output current will flow through the external resistor if it is smaller than the internal resistor; this is significant when the external resistor is small and the output current high. Nevertheless, a 0.25W resistor will be sufficient, since the power losses will not exceed 170mW even for a 250mA output current.

Constant-current drivers show a temperature dependence. At high temperatures the output current decreases slightly. The output current remains independent from the voltage drop across the driver, however. As the output current decreases with temperature, there is no risk of thermal runaway.

The minimum voltage drop across a constant-current driver is about 1.4V. Below this voltage, linear regulation does not work properly. Above it, the voltage drop across the constant-current driver dynamically adjusts to maintain the desired output current.

In low- and high-side configurations, the output voltage is always calculated as:

V_out = V_CC - V_LED

where:

V_LED = voltage at the LEDs and V_CC = supply voltage

Constant-current LED drivers are used when the brightness of an LED should be independent of the supply voltage to some degree. For example, the 12V power supply in a car fluctuates between 11V and 15V during normal operation. If the desired drive current and the voltage drop across the LEDs are known, the minimum possible supply voltage can be calculated by adding the voltage drop across the driver plus the voltage at the LEDs. The maximum allowed voltage is governed by the maximum-permitted voltage drop across the driver, or the total power dissipation, which can be estimated by the formula: P_tot≈V_out x I_out.

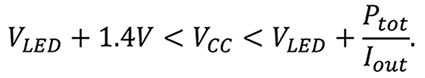

Hence the allowed operating range, if datasheet limits are not exceeded, can be specified as:

Constant-current drivers in the SOT457 package usually have a maximum power rating of 0.75W. For an output current of 50mA, this relates to a margin of 15V. Newly released devices in a SOT223 package from Nexperia have a higher maximum power rating of 1.25W, which raises the voltage margin to 25V.

Additionally, the voltage margin can be increased by reducing the output current. Placing two or more constant-current drivers in parallel, as illustrated in Figure 3, effectively doubles the current. Using this method, a current exceeding the capability of a single driver can be driven, or a smaller current per driver can be used to increase the voltage margin.

Fig. 3: Two low-side drivers in parallel operation

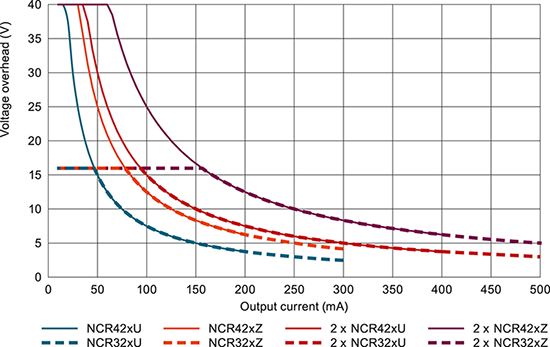

The use of two constant-current SOT223-packaged drivers with a drive capability of 250mA enables the circuit to drive 500mA LEDs with a voltage margin of 5V. When driving constant-current drivers in parallel, the accuracy of the external resistors is the most important factor for the symmetry of the output currents of the individual drivers. Figure 4 illustrates the voltage margins depending on the output current for single and parallel drivers in SOT457 and SOT223 packages.

Fig. 4: Voltage margin of single and parallel drivers in SOT457 and SOT223 packages

In conclusion, constant-current LED drivers off er a very low-cost and easy-to-implement solution for driving low- and mid-power LEDs. Using packages with a higher maximum power rating provides a higher margin in the supply voltage, and parallel drivers can be used to increase the current capability.

Fig. 5: Nexperia NCRx2xx LED drivers in SOT457 and SOT223 packages