By Steffen Hering

Business Development Manager, Future Electronics

Read this article to find out about:

- The efficiency, noise and reliability advantages of the PMSM motor type

- Future Electronics’ innovative implementation of field-oriented control for an 8-bit MCU

- The operation of the SPINnaker motor-drive reference design board based on an STM8S MCU

Industrial, automotive and medical equipment manufacturers which want to replace legacy brushed DC electric motors or block-commutated Brushless DC (BLDC) electric motors with a superior Permanent Magnet Synchronous Motor (PMSM) have in the past faced an unattractive trade-off.

In return for the superior efficiency, longer lifetime and higher reliability offered by the brushless PMSM, the designer had to accept a higher Bill-of-Materials (BoM) cost. This was because the complex mathematical calculations required to control an electronically commutated PMSM called for the high-speed data-processing capability of a sophisticated 32-bit microcontroller in most cases, and at the very least a 16-bit MCU.

This cost disadvantage put PMSMs out of reach of high-volume, low-margin applications. Now, however, Future Electronics has developed a form of Field-Oriented Control (FOC) for electronically commutating a PMSM which is hosted on a simple, low-cost 8-bit MCU. Suitable for motors rotating at a constant speed and subject to small load variations, the new SPINnaker motor-control reference system offers all the benefits of a PMSM of high efficiency, low noise and high reliability, at a BoM cost around half that of a 32-bit MCU-based implementation.

Now for the first time it is possible to implement a PMSM design running FOC commutation software in cost-constrained applications.

Commutation Options

It is in fact already possible to implement electronic commutation of a brushless motor on an 8-bit MCU. Block commutation, the simplest way of driving electronically commutated motors, has a low mathematical complexity and can be implemented on a relatively low-speed CPU, and is today commonly used to control BLDC motors. A BLDC motor has a different winding arrangement from that of a PMSM and is better suited to block commutation. But block commutation has several drawbacks which reduce its appeal to motor-system designers, as shown in Figure 1:

- Relatively high torque ripple

- Reduced efficiency

- Acoustic noise

Fig. 1: A typical block commutation pattern showing the sequential switching of the three phases of a BLDC motor, and the torque ripple produced by the switching operations.

FOC is a more sophisticated method for controlling a motor drive which off ers more attractive operating characteristics. Because the driver waveform is sinusoidal, the motor-drive system is quieter, more efficient, and produces no torque ripple.

This means that a PMSM is the best motor type to use when the application calls for precise control of a continuously spinning rotor, and when the motor needs to operate almost silently. Typical use cases will include a fan drive in the cabin of a car, in which the passengers value low acoustic noise; industrial production equipment, in which very precise control of position is essential; and when reliability is essential, such as in zero-maintenance or unrepairable pump drives, for instance in mining equipment.

Attractive as the sinusoidal FOC method shown in Figure 2 is, it is computationally intensive. FOC software typically occupies a Flash memory footprint of between 24kbytes and 60kbytes. It is normally realised through a complex control algorithm which requires the use of floating-point operations, trigonometrical functions, complex numbers and matrix operations.

Fig. 2: Sinusoidal commutation, in which the motor drive’s three phases are modulated for maximum torque and a flat torque profile at any rotor angle.

This would normally be the domain of a 32-bit MCU, yet Future Electronics, with the release of its SPINnaker motor-control reference design board, has developed a form of FOC software, operating on the Space Vector Modulation (SVM) principle, which runs on an 8-bit MCU.

The SPINnaker reference design system comprises a full-featured three-phase motor-driver daughterboard connected via a standard header to an STMicroelectronics STM8S-DISCOVERY development board for the STM8S family of 8-bit MCUs, as shown in Figure 3. Users can alternatively connect the motor-driver board to an STM8A-DISCOVERY board for the STM8AF and STM8AL families of automotive 8-bit MCUs, which are rated for a maximum junction temperature of 150°C.

Fig. 3: The SPINnaker motor-driver daughterboard.

In fact, the architecture of the SPINnaker software is MCU-agnostic and can be ported on request to other manufacturers’ 8-bit MCUs as well.

The unique SVM algorithm developed by Future Electronics controls the rotor speed, the current (flux), and the angle between the rotor and stator. Implementing proportional-integral control emulation, it requires no divider or other complex mathematical functions and is as a result a very small body of code: it occupies only around 7kbytes of Flash memory and 1.2kbytes of RAM.

Maximum resolution is 384 steps per revolution; the user can configure the software to off er lower resolution at higher rotation speeds. The standard software uses a UART interface to communicate configuration and system-monitoring data, although it can also transfer data via an I2C, SPI or LIN interface. The commutation software operates with a position indicator or sensor. Sensor-less operation is possible, but needs additional circuitry.

Of course, shrinking a complex control algorithm to fi t constrained resources inevitably entails some trade-off s. Compared to a 32-bit MCU implementation, the SPINnaker FOC software responds more slowly to changes in the load and maintains less precise control when the rotor’s speed changes rapidly. In addition, the system only provides data outputs once per revolution, not at every step as in a standard FOC system.

Nevertheless, as the performance test results below show, the SPINnaker control system maintains impressive speed control and stability when driving a motor at a constant speed and with little change in the load.

And the promise of BoM cost reduction is real: a Future Electronics comparison of a standard 32-bit MCU implementation with the SPINnaker system indicates that SPINnaker offers around a 50% cost saving.

Simple User Configuration

The SPINnaker motor-control software is backed by a PC configuration tool which makes it easy for the system developer to configure the motor’s operation, as shown in Figure 4. The GUI also displays graphs for monitoring the performance of the motor in real time.

Fig. 4: The configuration tool GUI provided by Future Electronics with the SPINnaker system.

The GUI includes sliders for selecting the required speed in rpm, the current in 256 steps/revolution, and the angle between the rotor and stator. ‘Damping’ is a feature which will be enabled in future versions of the SPINnaker software. The graphs on the right of the screen show the speed, angle and current relative to their maximum values.

Figure 4 shows the operation of the SPINnaker system under test conditions. A mechanical load increase induces a rise in the current value (1). After a brief and small variation in the field/rotor angle, the algorithm quickly brings it back to equilibrium (2). When the mechanical load is decoupled from the motor, the algorithm lowers the current (3), causing the angle between the rotor and stator to briefly diverge from its specified value before returning to equilibrium.

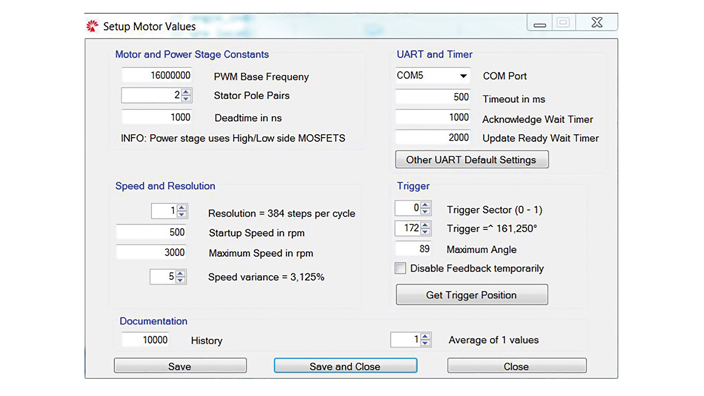

As well as supporting system monitoring, the SPINnaker configuration GUI enables the user to configure various motor characteristics, as shown in Figure 5. The control software also provides safety and protection features, such as automatic stall detection and overload shut-down, which generate user alerts in the configuration tool when active.

Fig. 5: The configuration tool provides many options for the user to modify the characteristics of the motor.

The SPINnaker system also provides for user monitoring of the data traffic between the control board and the motor-driver daughterboard, as shown in Figure 6. Detailed analysis of the data enables the developer to optimize the control sequences for specific operating conditions.

Fig. 6: Data traffic between the STM8S MCU control board (in red) and the motor-driver daughterboard (in black).

New Opportunity to Embed PMSMs in Low-Cost End Products

The introduction of the SPINnaker system from Future Electronics makes it possible for the fi rst time for a PMSM to be used in cost-sensitive and high-volume applications that previously were limited to the use of a brushed DC motor or block-commutated BLDC motor. Replacing these motor types with a PMSM enables the OEM to benefit from its attractive attributes: higher reliability, higher efficiency, lower EMI and lower acoustic noise.

Design engineers may apply to receive the SPINnaker board and software at Future Electronics’ www.myboardclub.com website for developers.