Resistors are a fundamental type of electronic component, and are critical to every electronic circuit in existence. Some resistors are old-fashioned wirewound parts soldered on to a PCB by hand; others are integrated into ICs directly in the form of polysilicon traces.

This article looks at the role of resistors in modern electronics designs, and describes how the latest Panasonic range of resistors can help engineers to reduce the cost of their products while making them more efficient.

Resistors in History

One of the oldest mass-produced type of resistors is the carbon-composition resistor. It consists of a cylinder made of a carbon/ceramic mix, which is bonded with a resin and a pair of metal caps with component legs attached to each end. While these resistors were useful in early electronics systems, such as amplifiers and radios, they soon gave rise to various problems.

It did not take long for the industry to respond, developing a wide range of resistor types, each with its own mix of advantages and drawbacks. Wirewound resistors are commonly used in power applications in which a standard carbon resistor would vaporize, while some metal-film resistors are popular in precision circuitry, which requires resistance tolerances of less than ±1%.

In fact, the resistor market today can dazzle even the most experienced engineer: parts are available in every conceivable shape and size, giving a suitable option for any specific application. To make matters more complex, technology is constantly changing. In particular, the growing interest in IoT technologies and solutions calls for a continual reduction in the size of electronics circuits. In addition, wearable electronics devices require flexible circuits and power systems that can handle more power in a smaller space.

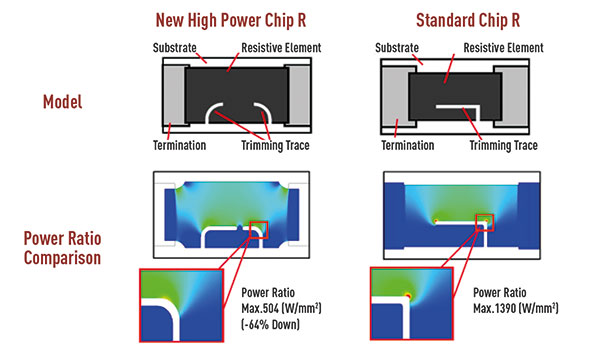

Fig. 1: New curved trimming trace almost entirely eliminates hot spots inside the resistor

A New Standard Line of Resistors from Panasonic

Panasonic is now releasing a new line of resistors to help engineers produce cheaper, smaller and more efficient designs. An older series of resistors, the ERJ line, has either been made smaller while handling more or the same amount of power, or its power-dissipation capability has been increased while maintaining the same footprint.

Panasonic was able to increase the power-dissipation capability of its surface-mount resistors by improving its trimming technology. Standard surface-mount resistors use straight lines in an L shape to trim the resistor to the specified resistance. The problem is that this shape has sharp corners of material which produce hot spots. Even though the rest of the resistor can handle more power, these hot spots cap the maximum power dissipation and the maximum pulse current.

Panasonic’s new trimming technique uses curved lines on both sides of the resistor, as shown in Figure 1. This almost entirely eliminates the hot spots because of an overall 64% reduction in their power ratio. What is more, this trimming technology also improves the pulse characteristics, allowing the ERJP series to typically handle double the power in the same case size compared to the earlier ERJ series.

The use of curved and meandering trims on the new line of resistors has enabled Panasonic to produce smaller parts that can handle more power, as shown in Figure 2. This has reduced their overall footprint and weight. For example, a product which today uses 10,000 standard 1206 surface-mount resistors can replace them with 0805 high-power parts and reduce the total weight by 40g, a 60% reduction, and occupy as much as 50% less PCB space.

Panasonic’s new line of resistors comes in several variations to serve different applications. For example, the ERJUP6 is a 0.5W resistor in a 0805 footprint with anti-sulfur and anti-surge capabilities. The ERJT06 is a 0.25W resistor also in a 0805 footprint, but aimed at anti-pulse applications.

The new line of ERJP resistors features tolerances as low as ±0.5%, and is available with resistance values ranging between 1Ω and 10MΩ. The temperature coefficient of resistance is ±100ppm/°C, and the operating-temperature range is -55°C to 155°C.

The new line of resistors, then, increases power capability and power density. But how do reduced resistor size and higher power dissipation help designers, and what can an engineer expect when using the new Panasonic line of resistors?

Fig. 2: Panasonic’s new resistors offer higher power density

The Benefits of Smaller, More Powerful Resistors

Using parts that are smaller and able to handle more power has many advantages, some of which are not obvious at first.

First, resistors such as the ERJP03 not only act as a potential drop-in replacement for the older ERJ3 with no need to change existing PCB layouts, but they can also handle more power. This means that they can be used to replace larger resistors or multiple small resistors connected in parallel. The reduction in part count can help to reduce bill-of-materials costs and the cost of the manufacturing process.

Replacing an older resistor such as the ERJ8 with a smaller resistor such as the ERJP06 that offers either the same or better power dissipation can have a dramatic effect on the design of a PCB. The use of smaller components can enable the use of a smaller PCB, which cuts its cost.

The saved space also helps to reduce the overall size of the circuit, which has a number of benefits. For one, smaller circuits often have smaller trace lengths, which can make it easier to meet EMC requirements.

Second, smaller circuits are more portable and easier to integrate into tight environments such as wearable electronics. If smaller components are used but the PCB size is kept the same, then the designer has the opportunity to integrate more functionality into the product and make its feature set more attractive.

Combining the use of smaller and fewer parts also has an effect on the production process. With fewer components in a smaller space, more PCBs can fit on a single panel, and pick-and-place machines can populate the PCB faster. A board that has fewer solder joints also has fewer potential points of failure both in production and in service. A cut in the number of solder joints also accelerates automatic optical inspection.

Implementation Examples

| The ERJPA2 is an 0402 surface-mount resistor capable of dissipating 0.2W of power. It is a potential drop-in replacement for the older ERJ2, or it can be used to replace the ERJ3 or ERJ6 if a smaller pad and higher power dissipation are desired. |

| The ERJPA3 is an 0603 surface-mount resistor which is capable of dissipating 0.25W of power. It is a potential drop-in replacement for the older ERJ3, or it can be used to replace the ERJ6 if a smaller pad and higher power dissipation are desired. |

| The ERJP03 is an 0603 surface-mount resistor which is capable of dissipating 0.2W of power. It is a potential drop-in replacement for the older ERJ3, or it can be used to replace the ERJ6 if a smaller pad and higher power dissipation are desired. |

| The ERJP06 is an 0805 surface-mount resistor capable of dissipating 0.5W of power. It is a potential drop-in replacement for the older ERJ6, or it can be used to replace the ERJ8 if a smaller pad and higher power dissipation are desired. |

| The ERJP08 is a 1206 surface-mount resistor capable of dissipating 0.66W of power. It is a potential drop-in replacement for the older ERJ8, or it can be used to replace the ERJ14 if a smaller pad and higher power dissipation are desired. |